It cannot be overstated that the quality of scale models (in this case, N, but generally any scale) is currently at an all-time high and still climbing. The steady advancement of technology has provided us with manufacturing capabilities unheard of just a couple of decades ago.

That said, what good is quality, one may rightfully argue, if accuracy is not keeping pace? This thorny, argument-inducing issue is loaded with valid points to make on behalf of folks on both sides of the fence.

In defense of the manufacturers, as in any business venture there's a point of diminishing returns. Even the largest model makers have finite budgets and resources. There is always a clear line in the sand beyond which the company begins to lose profitability on any given mass-produced product; the lower the development investment, the greater potential profit—and profit equals more goodies for us. It is therefore necessary for us to accept that there will be a "good enough" rule applied across the board. We must also expect to see at least some "fantasy schemes" so that products find the broadest possible market and generate the greatest ROI.

The "good enough" rule involves two aspects of production: research and tooling. There are just so many human-hours that can be invested in researching a model before the budget is blown. And as for tooling, there may be a point at which a scale-width hood becomes prohibitively costly to tool owing to hard stops such as motor size. Yes, it may be feasible to make the hood the right width, but that last six scale inches may come at the expense of a different, more costly motor or all-new tooling for a chassis that could have been recycled from another loco.

In defense of the modelers, many errors would cost nothing to correct: the right paint color or road number costs the same as paint of the wrong. As Mike Skibbe summed it up in a previous post, getting it right expands the potential market: it will then appeal to the prototype modelers as well as the casual consumers (which includes collectors) who enjoy the model just the way it is, warts and all.

Let's take a specific example: for September 2007, Micro-Trains released a CP Rail 89-foot trailer flat loaded with intermodal containers, number 521135. However, this number is part of a series used for AAR type P782 81-foot flats (center photo, CP 521133). If they'd wanted to get closer to reality, they should have used a number between 5217XX and 5223XX, which appear on CP Rail AAR type P880 89-foot flats (bottom photo, CP 521719). Although the CP Rail cars have open decks, unlike the models, Micro-Trains could have improved matters a bit by positioning the containers at the extreme ends of the car. (Top photo, Micro-Trains; center and bottom photos, Joe Rogers, Railroad Pictures Archive.)

This information was obtained after just a few minutes of online searching. Which raises a curious issue: the Internet has become an incredibly potent research tool. It certainly cannot be a huge strain on a manufacturer to spend some quality time with Google, yet obvious and presumably avoidable discrepancies continue to appear time and again. As another example, the number boards on a soon-to-be-released diesel are off the mark, as several photographs of the real deal clearly illustrate. What is the reason for this oversight?

Once again, the manufacturer may have had any number of limitations imposed on the model's production; much goes on behind the scenes, out of our view. With respect to the number board problem, older tooling is being recycled. In other situations, getting absolutely every aspect of the model accurate may not be feasible given time and budget constraints. And, since most tooling is done overseas, there may be communications problems or quality control issues on the contractor's end. We could not hope to know all of the details.

Let us not overlook, too, the fact that tooling is an art form, despite being the domain of computers these days. Blueprints and photographs must be interpreted by humans before tooling can commence, and the results reflect the skill of those individuals responsible for the interpretation. Layer on the complicating factors of fitting everything over a mechanism designed by other engineers, and you have ample opportunities for the model to drift astray from reality. To see all of this in practical form, take three models of the same locomotive from three different manufacturers: they should all be identical, or nearly so, yet each is different—sometimes subtly, sometimes radically. Why? It's the quality of interpretation.

But take heart, as we may be witnessing an opportunity to make everyone happy, or perhaps at least happier. Online forums are being frequented by both manufacturers and their customers. This free exchange of information and perspective may provide the means for even better, more accurate models. But this assumes one thing: everyone remains civil. It seems inevitable that some hot-headed rivet-counter starts spouting off about how incredibly stupid everyone is at XYZ Company for having gotten the stenciling on a gondola wrong. If I were a manufacturer, I would not be inclined to go the extra mile to satisfy people like this. Would you?

All of this has given rise to one overarching question in the back of my mind: Why are some modelers getting so fussy? Our models are better-looking and more accurate than ever before. Are we becoming jaded? With a cornucopia of steadily-improving products, are we now beginning to expect too much? It used to be that prototype modelers were generally content to modify their models as needed to achieve accuracy. Now it seems some won't even buy a product unless it is perfect right out of the mold. What they don't seem to realize is that they're shooting themselves in the foot; not supporting a model maker reduces the chances of seeing more products, let alone better ones.

Photos are illustrative G scale trains buildings

Photos are illustrative G scale trains buildings

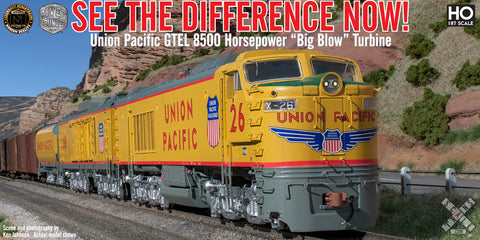

Photos are illustrative Ho scale trains voltage

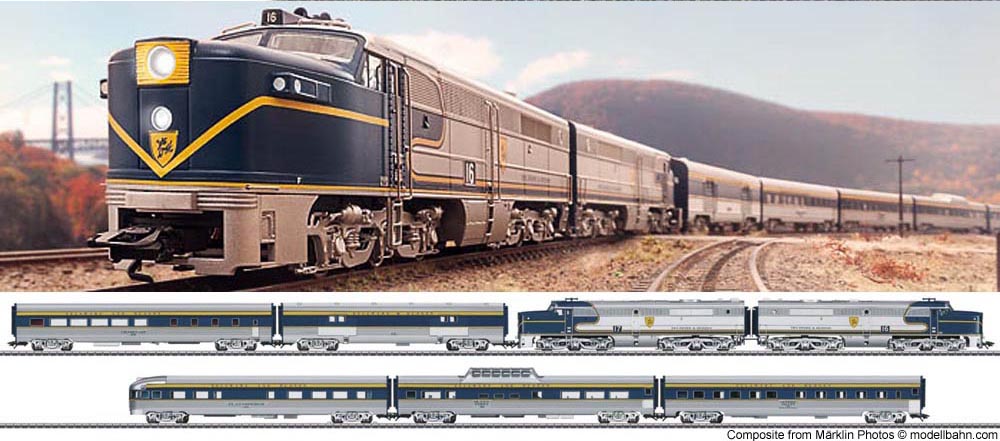

Photos are illustrative Ho scale trains voltage