Remember while reading this that I operate very slowly with momentum and braking and brakemen, so it doesn't take long trains and huge staging tracks to eat up considerable time playing trains. Here's how the traffic balancing gets thought about and implemented on my layout.

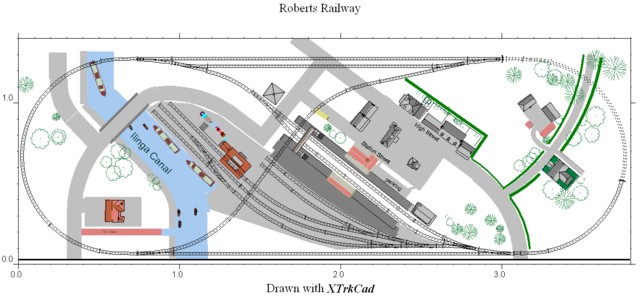

I have an AM and a PM switch list for each operating area, and I have up to 11 operating positions now in 7 operating areas on my 500 (+ 200) sf layout. (I am slowly taking over the hallway, which has gone from temporary to permanent so slowly that my wife is just now realizing after 2 years what has happened with that extra 200 sf...ssshhhhh!)

The operating areas are yard, Bethlehem Steel, Maxwell House Coffee, float yard, docks and two remote pocket terminals Harlem Station and Lehigh Valley West 27th St Yard. I'll pick those pocket terminals off first as low hanging fruit explanations.

My current car float holds 6 cars, so they have 6 cars to place and 6 to pick up and put on the float. That sets each 'round' at 12 car movements, which takes about 1.5 hours for Harlem Station, which can hold about 50 cars max. (I haven't operated the 27th, yet) from what I can tell after a couple of sessions. I can cycle that twice for a 3 hour session. Those cars are coming from the float yard on the HBS, so I know I need to get about 6 cars for each yard there half way through - or more likely, already have at least some of them there. I'll probably have float cut-off times that need to met when/if I have a clock. So the pocket terminals are easy.

Most of the switch lists for the last operating session

For the next operating area, the yard has shorts inside the yard to work, which has about 2 dozen spot locations. I have about 1/3 of that filled with cars at any given time. The last switch list for AM was the 14th Street job which had 5 pickups and 4 set outs.

The PM list, which is made up of cars from the Interchange Yard that should be there by the PM, was for the yard short job with about 2 dozen spot locations, which are industries not on 14th St and are accessed in the yard. There were 5 pick ups and 7 set outs. This job wasn't even started last session, because they yard was busy. No problem, it is ready for next time.

With all those available spots, it is easy to balance pick ups and set outs and not overfill anything. Cars that don't get moved this session I will know should be moved next session, but it doesn't really matter to anyone but me who is keeping track of those things...

So the other areas are basically governed by the ruling 18" radius curve on the layout which restricts my 44 tonner train lengths to about 10 cars due to friction. At Bethlehem I have 12 spots, so I move half each switch list - I just randomly pick which cars to move. On the last switch list there were 5 set outs and 5 pick ups. I just made sure no track would get too full.

Since this is a busy industrial operation, cars could actually get loaded/unloaded during a session and move again without much operator angst. (I am thinking about having a timer.) In fact, I want to model some of that at Maxwell House where empties and full cars would get shuffled during a session like Chuck Hitchcock's grain elevator operational design element. Again, train lengths are about 5-6 out and 5-6 in from Maxwell.

I have 4 areas on the 'main line' that get served by up to two, two-man crews. I alternated them so there is less aisle crowding. Rinse and repeat for those 4 jobs with the philosophy that these locomotives are running back and forth all day on this short railroad with a handful of cars each time. The YM simple keeps writing switch lists for crews to work as soon as they get back to the yard.

I believe I could operate for 6 hours straight without re-staging if I try. I can always re-stage in the middle of a session just by doing some mole activity in the Erie Weehawken Yard. There are 12 spots there and 16 in the Interchange Yard, plus I don't know how many in the HBS Yard. If I maxed out everything, I could operate that 6 hours easily. I should try some day having back to back crews in... hmmm.

So all of the balancing is about each job and it takes place in my head, but it is a small railroad, so that's not too hard. I think it takes about an hour to an hour and a half to stage.

As far as keeping track of things in the yard, I may use a chalkboard at the pocket terminals to keep track of things, because that's how they did it. Then the crews can make up their own switch list from there, or just look at the chalk board... Maybe the same in the yard so the switchers can see it, too. I don't know, yet... Stay tuned!